Special UPVC Raw Materials

مواد خام خاصة UPVC

POLYVINYL – Stabilizer- impact- Titanum

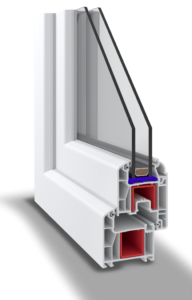

-Fields of Application:

-Window and door profiles – in white color

-Window and door profiles – in various colors

-Window profiles produced using co-extrusion technology (Coextrusion)

-Window profiles made from foamed PVC – using either Free Foam or Celuka methods

-Wood-like profiles made from PVC material (PWC)

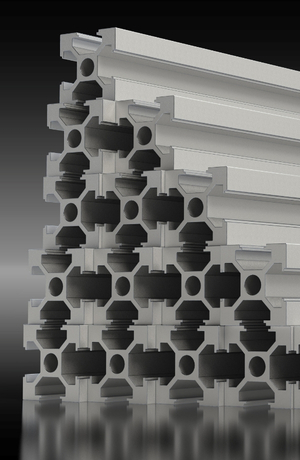

We develop high-quality, environmentally friendly aluminum solutions to meet the needs of industrial products and architectural projects.

Through advanced aluminum extrusion processes, we efficiently fulfill the demands of the sector, leveraging the latest technologies and cutting-edge alloys to deliver aluminum profiles known for their durability, aesthetics, and versatile functionality.

We have become a trusted name in the aluminum profile industry, making a clear impact with our expertise in designing custom profiles and integrated construction systems.

Special UPVC Raw Materials

Stabilizers for Window and Door Profiles

Ready-to-use One-Pack Stabilizers

Calcium/Zinc-Based Stabilizers (Ca/Zn)

These stabilizers are specifically formulated to perform efficiently with filler levels up to 75 phr and are used in window profiles that require excellent mechanical properties.

Fields of Application:

White-colored window and door profiles

Colored window and door profiles

Coextruded window profiles

Foamed PVC window profiles – produced using either Free Foam or Celuka methods

Wood-patterned profiles made from PVC (PWC)

Our stabilizers ensure consistent performance, weather resistance, and long-term durability, making them ideal for modern UPVC profile production needs.

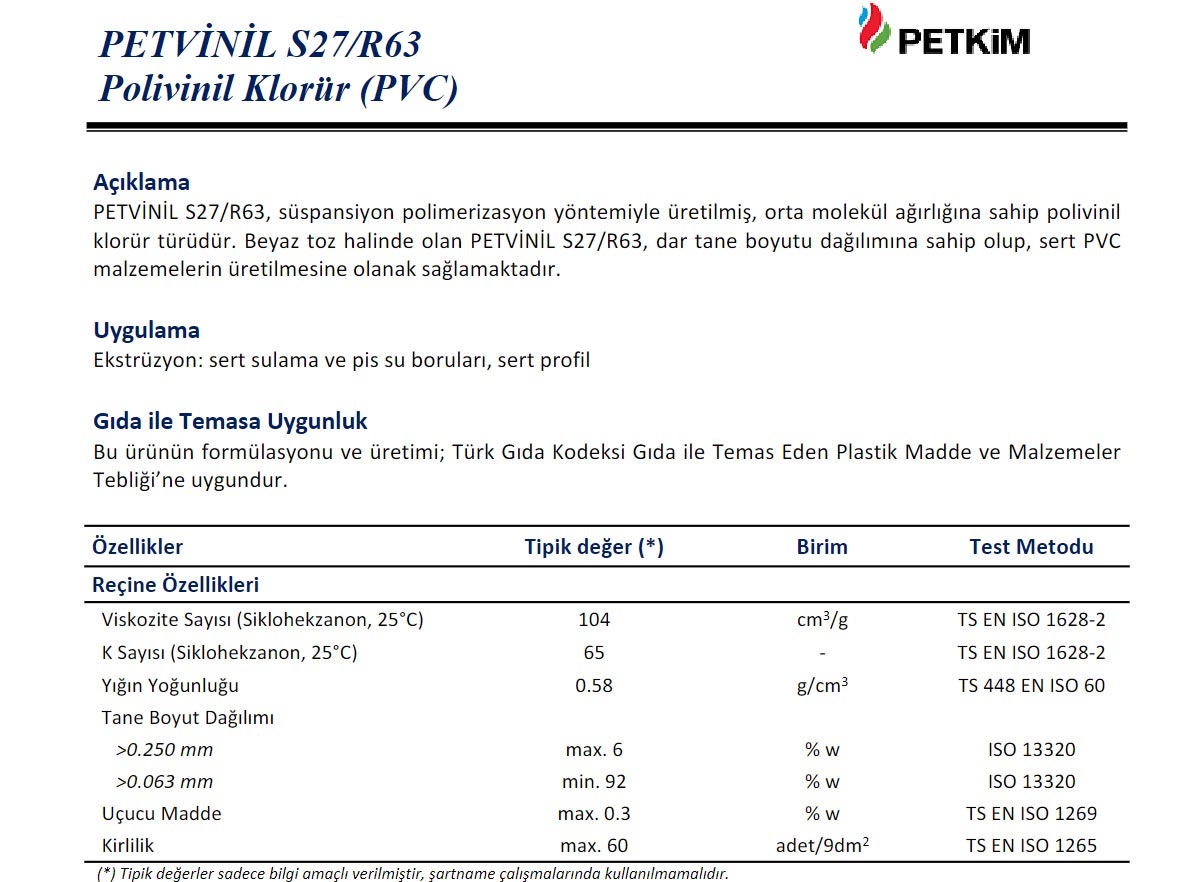

Polivinil Klorür

In an era defined by rapid advancements in efficiency and a continuous drive for more effective production alternatives, Parlakplast is making dedicated efforts to deliver solutions that empower its clients to optimize supply chain management by enhancing outcomes and overcoming challenges.

Each Parlakplast One-Pack stabilizer for PVC features a unique formulation composed of a blend of stabilizing compounds, antioxidants, internal lubricants, and external lubricants—offered as a single, ready-to-use additive.

Parlakplast stabilizers eliminate the need for weighing and mixing each component separately, significantly reducing the risk of errors during processing. This not only saves time and energy but also helps lower production costs and increase operational efficiency.

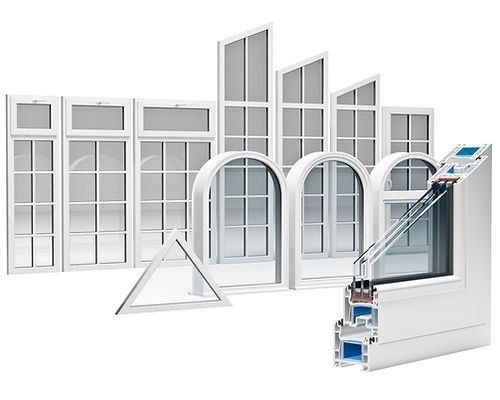

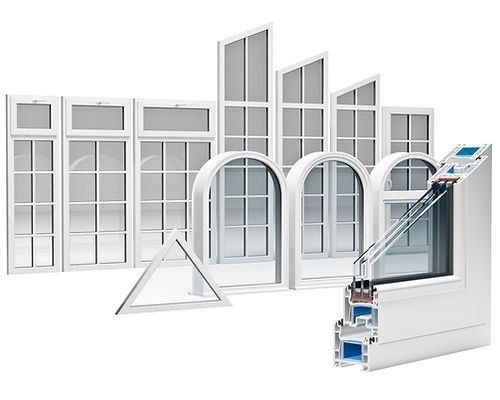

High-quality window products with a variety of accessories

Smart windows with tilt-and-turn functionality

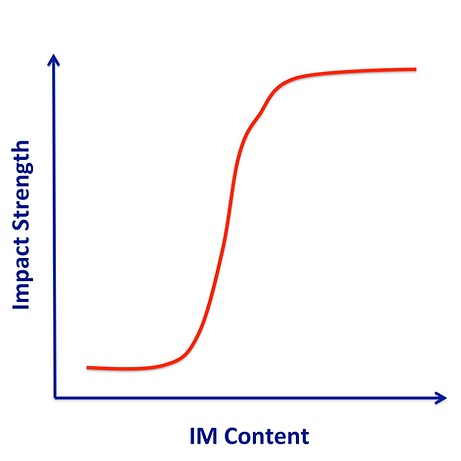

Impact Modifiers

Enhancing the impact resistance of PVC is one of the key areas where Parlakplast’s high-quality impact modifiers truly excel. These modifiers work by redistributing shock energy throughout the PVC matrix, resulting in superior impact strength and outstanding weather resistance. This makes them ideal for rigid PVC applications that demand premium quality, high gloss, and long-lasting durability.

When combined with KİMFLOR One-Pack PVC stabilizers, these impact modifiers deliver high production rates, ease of processing, and excellent stability from the initial preparation stage through to final processing.

They also contribute to a smoother PVC manufacturing process by simplifying weighing, handling, and dosing operations—boosting production efficiency while minimizing waste.

For more information or assistance in selecting the right product, don’t hesitate to contact us — we’d be happy to support you based on your specific needs.

Best choice for you comfort